Oct012014

Posted at 12:50 PM

Post by Dr. Sue Helper

This week, as we celebrate the country’s vital manufacturing sector, we are excited to unveil a new tool that will allow manufacturers to calculate potentially significant savings that can be realized by manufacturing in America.

With the first iteration of Assess Costs Everywhere (ACE), we assisted manufacturers in deciding where to locate their operations by examining 10 cost and risk factors they should consider. This week, we present “the Cost Differential Frontier,” or CDF, as part of ACE 2.0. Developed by economists at the University of Lausanne, this calculator serves as a framework to consider total inventory costs and risks.

ACE 1.0 examined factors such as labor; trade financing and regulatory compliance costs; product quality; shipping; travel and oversight; inventory; intellectual property; political/security risks; and other inputs to gain a better understanding about the sometimes hidden costs associated with manufacturing location decisions. Great work is underway to further our understanding of the financial implications of these factors. Applying CDF, businesses for the first time can quantify potential savings that would be derived from reducing lead time, in conjunction with other factors.

Because customer demand often fluctuates unexpectedly, companies should carefully consider the value of a domestic supply chain with shorter lead times. Using offshore suppliers increases the time between order and delivery, often by months. As a result, the buyer must place the order based on a forecast. As the lead time gets longer, the range of demand levels that must be considered becomes wider. These fluctuations lead to costly stock-outs or overstocks. The savings from offshoring may need to be large (20 percent or more) to compensate for these mismatch costs between supply and demand. Applying CDF, manufacturers can calculate exactly how the long supply chains and uncertainty add large hidden costs to production.

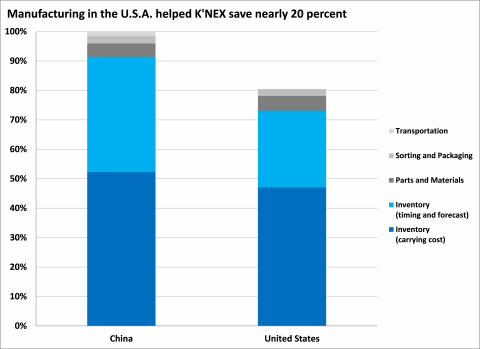

Moreover, real-life examples such as the successful reshoring story of U.S. toy manufacturer K’NEX demonstrate that the promise of ACE is more than just theoretical. Indeed, with ACE and CDF, a truly compelling case for reshoring is emerging.

Recently U.S. toy manufacturer K’NEX had an opportunity to show the value of CDF. K’NEX Brands is a family-owned construction toy company located in Hatfield, Pennsylvania, just outside of Philadelphia. Since 2009, K’NEX has re-shored most of its toy construction from China to Pennsylvania, and now manufactures 90 percent of its own parts and 80 percent of its finished products in the United States.

This re-shoring resulted in cost savings associated with inventory, forecast accuracy, and timing of almost 20 percent. Suppose the cost of producing in China is 100 (as illustrated in the figure). The inventory costs required to offset the risk of running out of product (called “timing and forecast” in the figure), accounted for costs equal to 39 in China but only 26 in the United States. The reason the savings were so large is that when the product was coming from China, K’NEX had to guess up to 22 weeks ahead what its customers might demand. Not wanting to risk losing a sale, K’NEX ordered a lot of extra product that might not ever be sold. Now, K’NEX can wait to commit production until it has full knowledge of demand.

The K’NEX story highlights the high inventory costs dictated by offshore manufacturing and long lead times. Bringing together the mathematically rigorous insights of the CDF tool and the real-world experiences of K’NEX helps us understand just how large these costs can be, and the potentially huge savings resulting from reshoring.

The CDF was developed by Professors Suzanne de Treville and Norman Schürhoff of the University of Lausanne, and has been tested by Professor de Treville and her laboratory in a variety of multinational companies. Professor de Treville served as a visiting professor at MIT during the spring of 2014, during which time she worked intensively with the Department of Commerce to make the CDF available through Acetool.